Ultrasonic Testing Service

Ultrasonic Testing (UT) process is used to detect internal flaws, measure material thickness, and evaluate the structural integrity of components without causing any damage. As a Professional Ultrasonic Testing service provider, ITE Noida offers critical inspection solutions for industries such as oil & gas, power generation, aerospace, automotive, manufacturing, and construction, ensuring safety, reliability, and compliance with international standards.

Ultrasonic Testing Services

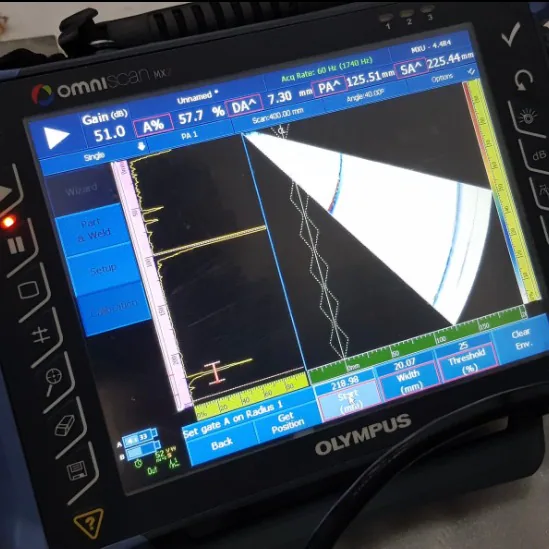

Ultrasonic Testing process is a highly effective non-destructive testing (NDT) method that involves transmitting high-frequency sound waves into a material using a transducer. When these waves encounter a defect—such as a crack, void, or inclusion—they reflect back and are captured by the equipment. These reflections are analyzed to determine the size, location, and type of flaw. This process is especially valuable for inspecting welds, pressure vessels, pipelines, forgings, and castings.

Inspection & Testing Engineers offers High Accuracy Ultrasonic testing service for internal flaw detection and thickness Measurement for corrosion and erosion monitoring. We are one of the leading Ultrasonic Testing service providers, use manual, automated, or phased array ultrasonic testing (PAUT) methods, depending on the application. Our certified technicians (ASNT/ISO Level II or III) ensure reliable, code-compliant results. We provide services that may be conducted in-house or on-site, depending on project requirements.